Introduction

When businesses and individuals order custom stickers, they are often faced with two primary shape options—rounded stickers and straight cut stickers. While the difference in shape may seem cosmetic, it affects both production complexity and cost. One of the most common observations among customers is that rounded stickers are typically more expensive than their straight cut counterparts.

This article explores the key differences between rounded stickers vs straight cut stickers, including how they’re produced, the reason behind the cost discrepancy, and when each option makes the most sense for your branding or packaging needs.

Sticker Production: A Shared Beginning, Different Ending

At the core, both sticker types start the same way:

-

Designing the Artwork

– Done using professional graphic design tools.

-

Printing on Sticker Material

– Using vinyl or adhesive paper, sticker designs are printed in batches.

-

Cutting into Shape

– This is where the paths of straight cut and rounded stickers diverge.

The cutting process is what determines cost, time, and complexity.

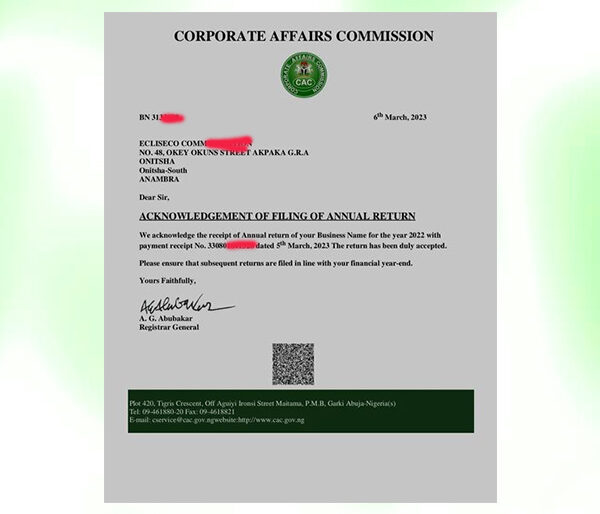

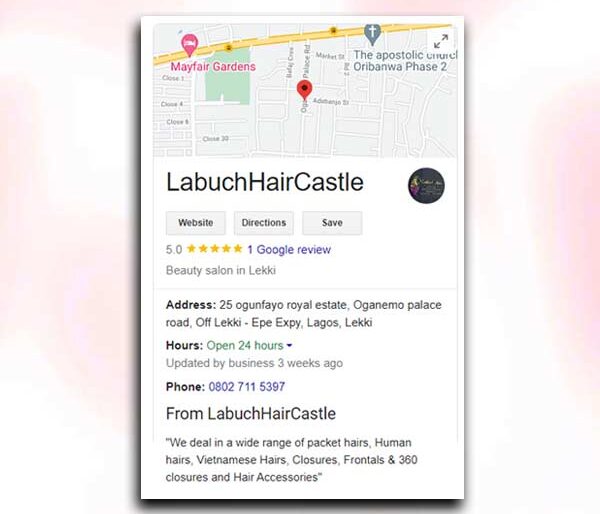

Our Top Selling Services

Straight Cut Stickers: Simplicity in Precision

Straight cut stickers are either square or rectangular, with sharp, 90-degree edges. Here’s why they’re typically more affordable:

-

Straightforward Cutting Process

The cutting is done using a plotter or guillotine machine that traces and cuts along pre-programmed vertical and horizontal lines.

-

Minimal Human Labor

Once the layout is set, dozens or even hundreds of stickers can be cut simultaneously in just minutes.

-

Reduced Waste

Straight cuts use the material efficiently. Since the shapes are simple, there’s very little leftover material after cutting.

-

High Speed Output

Speed equals cost-efficiency. Production time is shorter, which helps reduce overhead and client charges.

Rounded Stickers: Aesthetic Appeal Meets Extra Cost

Rounded stickers, on the other hand, usually require die-cutting, a more involved and manual process. They can be circles, ovals, or custom curved shapes.

-

Specialized Die-Cutting Machines

Die-cutting involves pressing a custom steel blade (die) into the material to carve out each sticker individually. This process is slower and more complex.

We recommend this for you

-

Labor-Intensive Execution

Cutting rounded edges requires manual alignment or semi-automated handling, especially for irregular or custom designs.

-

Material Waste

Rounded cuts often leave more unusable space around each shape, increasing material wastage. This leads to printing more than needed to meet your final count.

-

Human Error & Reprints

The risk of human error in die-cutting is higher. Misalignments mean some stickers may be wasted, and extra prints are necessary to meet accurate quantities.

Why Are Rounded Stickers More Expensive Than Straight Cut Ones?

Here’s a point-by-point comparison:

Have you Read this ?

Cutting Complexity

- Straight Cut: Simple and linear, minimal setup required.

- Rounded Stickers: Requires custom dies and precision cuts.

Production Speed

- Straight Cut: Faster and can be batch-produced efficiently.

- Rounded Stickers: Slower due to individual die-cutting.

Material Efficiency

- Straight Cut: Maximizes space and reduces waste.

- Rounded Stickers: Leaves gaps and unused edges.

Labor Requirement

- Straight Cut: Machine-led with minimal manual input.

- Rounded Stickers: Often manually loaded or aligned, increasing labor hours.

Error Rate and Reprints

- Straight Cut: Low error margin.

- Rounded Stickers: Higher chance of miscuts or inconsistent edges.

When Should You Choose Rounded Stickers?

Despite the extra cost, rounded stickers offer unique benefits:

- Brand Appeal: Rounded edges often appear friendlier, modern, and sleek.

- Custom Branding: Die-cuts can follow the shape of a logo or icon, making it stand out.

- Creative Designs: Circles and curves are visually attractive for labeling, packaging, and promotional use.

- Perceived Value: They tend to feel more premium in hand and on product packaging.

If aesthetics and brand impact are a priority, rounded stickers may be worth the extra investment.

When Are Straight Cut Stickers the Better Option?

- Budget Projects: If cost is a concern, straight cut stickers deliver value.

- Functional Use: For shipping labels or basic product IDs, straight lines work perfectly.

- Bulk Printing: They’re ideal for high-volume printing where efficiency is key.

Real-Life Example: Why One Client Switched to Straight Cuts

A client once ordered 5,000 rounded product labels for a seasonal promotion. While the design looked stunning, production delays and cost overages made them reconsider. For their next campaign, they opted for square stickers using the same design and saved 25% on cost while meeting the timeline. The visual difference was minimal for the use case, but the savings were significant.

Tip: Use a Trusted Sticker Printing Service

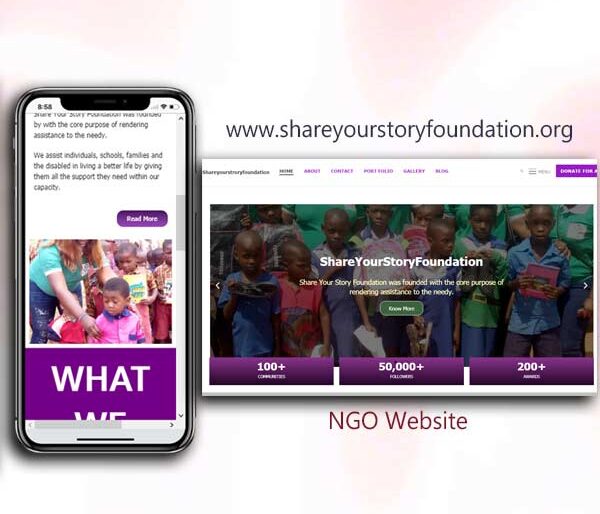

The quality of your sticker—rounded or straight-cut—also depends on the service provider. Opt for a provider that explains your options clearly, offers transparent pricing, and guides you through material and finish selections to optimize both aesthetics and cost.

At Zfrica, we offer printing solutions that include both rounded and straight-cut stickers, helping you select the best format based on your goals and budget.

Conclusion

When choosing between rounded stickers vs straight cut stickers, understanding the cost structure behind each option can help you make an informed decision. Rounded stickers offer elegance and design versatility, while straight-cut stickers deliver speed, simplicity, and cost-effectiveness.

The difference lies in the cutting process, equipment involved, and material efficiency—all of which influence the final price.

Whether you’re branding a product, organizing an event, or simply personalizing your gear, the right sticker shape can add that extra flair—or help you save costs where needed.

Frequently Asked Questions (FAQs)

Why are rounded stickers more expensive than straight cut ones?

Rounded stickers require die-cutting, a more complex and labor-intensive process. They also generate more material waste and require extra handling, increasing overall production cost.

Are there any benefits to using straight cut stickers besides cost?

Yes. Straight cut stickers are easier and faster to produce, ideal for bulk printing, shipping labels, or applications where aesthetics are secondary.

Can I get rounded stickers without using die-cutting?

Some digital cutting tools can mimic rounded shapes, but for perfect edges and custom shapes, die-cutting remains the most reliable option.

Is the sticker material different for rounded vs straight-cut stickers?

No. Both types use the same base materials (vinyl, adhesive paper, etc.). The difference lies solely in how they’re cut after printing.

What if I want a custom shape that’s neither rounded nor straight?

You’ll still need die-cutting. Custom shapes fall under the same category as rounded stickers in terms of complexity and pricing.

Does sticker shape affect how well it sticks or lasts?

Not directly. Adhesion and durability depend more on the material and finish than the shape. However, rounded edges may resist peeling slightly better over time.